Peel Testerpurchasers|wheel peel testing kit : Brand manufacturer Mark-10 Peel Testers are suitable for T-peel, 90°, 180°, and variable angle peel testing applications. Configure your peel testing systems from a wide range of test frames, force . You can bet live on sports and hit the jackpot online on the 2.

{plog:ftitle_list}

WEB13 de set. de 2023 · Concurso 77. Acumulou! Informações sobre o sorteio do concurso 77 (13/09/2023) da +Milionária - Resultados do sorteio, números, datas, premiações e .

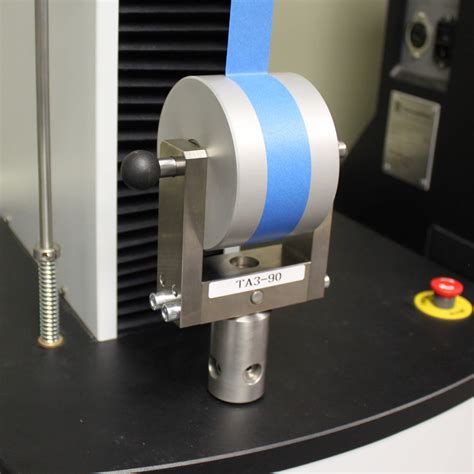

Choose from a variety of peel test machines that meet your specifications and budget. Peel testers, or peel test machines, are universal test machines specially configured to determine .We carry testing equipment for measuring peel strength, including 90 & 180 degrees, T-Peel, etc. to test adhesive properties of materials. Request a quote.

Mark-10 Peel Testers are suitable for T-peel, 90°, 180°, and variable angle peel testing applications. Configure your peel testing systems from a wide range of test frames, force .Peel Strength: While not directly measured, peel strength is a key metric calculated from the peel force and the width of the sample. It is usually expressed in N/mm or N/m. The average peel strength across the test can provide a . No Additional Cost: You pay nothing for repairs – parts, labor, and shipping included. Coverage: Plan starts on the date of purchase. Drops, spills and cracked screens due to normal use covered for portable products and . 90 degree peel tester . model pa-2000-90 . operating instructions . cheminstruments . 510 commercial drive . fairfield, ohio 45014 (513) 860-1598 . www.cheminstruments.com

wheel peel testing kit

Peel strength is the average load per unit width of the bond line required to gradually separate a flexible member from a rigid member over adhered surfaces. It is calculated by measuring the average force required to peel the sample divided by the bond (i.e. adhesive) width. Peel strength is expressed in the following units: kilograms per .

влагомер wile 55 цена

Measuring peel adhesion strength is necessary in determining which adhesion is best suited for its desired end use application. ATS and ASTM Peel Adhesion Testing. Since 1967, ATS has delivered testing, inspection, and engineering consulting services of unmatched quality. During the 50+ years since our founding, we have expanded our client base .The Peel Seal Adhesion Strength Tester is an innovative instrument which helps in measuring the adhesion Strength or peel ability of self-adhesive pressure sensitive materials. Peel adhesion is defined as the force required to test the strength of the adhesives. The instrument consists of two jaws that are used for holding the sample.

IMADA is a specialized manufacturer of load testing. We manufacture products to realize various load tests such as compression test, tensile test, and peel test. IMADA load testing machines are used in the fields of quality control and research and development all over the world. 4. Use the Up and Down Arrow keys to change the length of the peel displayed. The choice for test length is (Range=0.5-4.5 inches in 0.5 inch increments) 5. Remember that this value is the length of the peel that data will be collected, not the entire length of the sample. 6. Press the Enter key to record the chosen setting. The PA-1000-180 is .Our digital peel testers are supplied with a dedicated library of pre-programmed peel test setups and advanced analysis software displaying test results as graphs. By adding the proper set of fixtures that matches the shape and size of your sample, our peel testing machines can go from measuring small samples to large samples.

Significance and Use 5.1 These test methods are tools for quality assurance use. Given specific pressure-sensitive tape and a requirement in terms of the minimum or maximum peel value expected for this tape, the data from the test can be used in conjuncti180°-peel. The 180-degree peel test quantifies the force required to peel apart bonded materials at a right angle to the bond. It can be used to examine the binding between a flexible material and a hard substrate. 90°-peel . The 90-degree peel test is a method for calculating the unit force required to tear apart bound materials at a 90 .The 90° peel fixture is designed to help an operator align and clamp down a specimen quickly and consistently while ensuring that a 90° angle can be maintained from start to finish. With its improved clamping and specimen alignment aides, the fixture provides greater repeatability, throughput, and reduced operator involvement over a standard .We have purchased Peel tester from them at reasonable price. Now, it’s easy for me to test the adhesive bonds between the materials. Our bond with Presto is as strong as our adhesive strength. For the past few weeks, we have been looking for a reliable manufacturer for peel strength testing. After weeks of searching, we found Presto peel tester.

ASTM D3167 is a standard test procedure used to measure the average peel strength or force of an adhesive and bonding agent by using a floating roller peel fixture. This test can be used to compare adhesives or to compare adhesive surface preparation procedures. ASTM D3167 is therefore often used in product development and manufacturing procedures. ASTM D3167 is . 4. Use the Up and Down Arrow keys to change the length of the peel displayed. The choice for test length is (Range=0.5-4.5 inches in 0.5 inch increments) 5. Remember that this value is the length of the peel that data will be collected, not the entire length of the sample. 6. Press the Enter key to record the chosen setting. The PA-1000-180 is .According to ASTM D3330, specimens for the peel test must be prepared from pressure-sensitive tape of a specific size in order to measure the peel adhesion. The exact dimensions of the specimens vary according to the test method .

ASTM D1876 is a test method that measures the peel separation strength of two flexible materials that have been bonded together. This is commonly referred to.Peel Tester is a specialized equipment for peel testing of numerous types of seals, adhesive tapes, and similar. The sampling speed is as fast as 2000 Hz, so that the peel strength can be quantified more precisely. The dedicated software is included to graph peel strength and output the maximum, minimum, and average values (also including a field to input the tape width, so .

Peel strength, the average force required to separate two bonded materials from one another, is a property applicable to various industries including aerospace, automotive, adhesives, packaging, biomaterials, microelectronics, and more. Peel test data is used to determine the quality of the adhesive joint and, where applicable, provides information on the effects of processesConfigure your peel testing systems from a wide range of test frames, force sensors, grips, and accessories. See the list of items below for details. Shown at left: F305-IMT test frame with an FS05-20 force sensor and G1008 film and paper grips. Mark-10 .Set of 10 Orange Peel Standards for visual reference. Perfect for liquid coatings, allows for evaluation on small and complex parts. Ranging from 1 to 10, these standards help measure the amount of orange peel of a given surface. A peel strength tester, also known as a peel tester or peel adhesion tester, is a specialized piece of equipment designed to determine the force required to peel apart the layers of a material or seal. It is a valuable tool for quality control and product development across various industries. How to Use a Peel Strength Tester Prepare Your Sample:

Peeling takes a wide array of forms. In the most basic sense, a peel test can consist of (1) a laminate comprising of two (or more) layers peeled apart, often at the interface or (2) an adhesively bonded joint in which two substrates are joined by an adhesive layer and then peeled apart, or (3) peeling of a single, adhesive material from a substrate or itself.SPEC-1 Entry Level Slip/Peel Tester: SPEC-1 is for users who want IMASS precision and quality but don’t need all the features of our other models. SPEC-1 is priced to compete yet preserves IMASS’ traditional technical advantage and ability to exceed industry test specifications. While primarily directed toward QC labs and .

ASTM D903 is a common tensile test used to evaluate the peel or stripping characteristics of adhesively bonded materials used in a wide variety of applications in an even wider range of industries. Some examples of materials tested to ASTM D903 are plastic films, adhesive labels, and waterproofing materials.Peel test fixtures measure peel and adhesion properties of adhesives. Max Force Capacity. 5 kN (1125 lbf) Sample Type. adhesives. 12 results - showing 1 - 12. Need Help? Talk to one of our Application Engineers to help you find the right solution for your test applications. Contact Us Now. CALL NOW.The Mark-10 G1045 90° Peel Tester is designed for applications in the packaging and food and beverage industries. Typical applications include the testing of adhesives, films, and packaging, such as foil seals found on yogurt containers, juice containers, and others

webTo book a delivery of sand and gravel etc please call us on 01202 937503 or 07836 329528. POOLE, CORFE MULLEN, BROADSTONE, OAKDALE, UPTON, BRANKSOME, MERLEY, BOURNEMOUTH, KINSON, WINTON, CHARMINSTER, NORTHBOURNE, WESTBOURNE & MORE. with over 25 years experience in the industry, based in Poole, Dorset, .

Peel Testerpurchasers|wheel peel testing kit